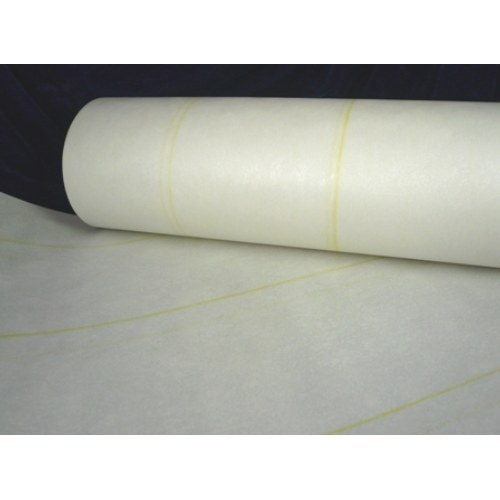

Food Packaging Laminates

Food Packaging Laminates Specification

- Product Type

- Food Packaging Laminates

- Processing

- Multiple Extrusion and Lamination

- Transparency

- Transparent, Opaque (Customized)

- Hardness

- Soft

- Lamination

- Multi-layer Laminated

- Customized

- Yes

- Standard

- Industry Standard Packaging Grades

- Film Length

- Up to 2000 meters (customizable)

- Film Thickness

- 20-250 microns

- Film Width

- Up to 1300 mm

Food Packaging Laminates Trade Information

- Minimum Order Quantity

- 300 Kilograms

- Supply Ability

- 1 Kilograms Per Day

- Delivery Time

- 1 Days

About Food Packaging Laminates

Backed by our team of meticulous professionals, we are instrumental in developing best quality Food Packaging Laminates . We have established a quality oriented business philosophy and make sure to procure 100% food grade certified raw material for our offered food packaging products. In addition to this, we have invested in modernized technology that enables us to present pouch and roll forms of varied types of laminates including Pet, Met Pet, BOPP, HS - BOPP, Alu-Foil, CPP and PE. Further, these rolls and pouches can be ordered from us in customized sizes.

Specification

| Industry | Food,Pharma,Pesticides,Dairy,And Industrial Use |

| Pattern | Printed |

| Additional cost Items | Dye Cylinder Cost |

| Base Material | LDPE |

| Colors | All colors available |

| Design | Customized |

| Pouch Lamination | Multi Layer Lamination |

| Pouch Pattern | Printed |

| Pouch surface Finish | Glossy |

| Size | Customized |

| Thickness | 10 Micron to 200 Micron |

| Type of Pouch | 3 Side Sealed Pouch |

- Attractive print quality

- Remarkable shelf appeal

- Heat resistant

- Glazed surface

Other Details:

- Made from 100% Food Grade certified raw material

- Can be supplied using a variety of substrates like Pet, Met Pet, BOPP, HS - BOPP, Alu-Foil, CPP, PE etc.

- Can be supplied in Roll Form as per customers requirement

- Can be supplied in Pouch Form as per customers requirement (Center Seal, Three Side Seal, Standup Pouch, Zipper Pouches etc).

Versatile Material Combinations

Using advanced multilayer structures such as PET/PE, BOPP/PE, and PET/Al Foil/PE, our laminates provide tailored barrier and mechanical properties. This versatility allows us to meet diverse requirements across snacks, spices, dairy, and pharmaceutical sectors, maintaining freshness and extending shelf life.

Exceptional Barrier and Sealing Performance

Our food packaging laminates deliver excellent protection against moisture, gas, and aroma transmission. Equipped with heat-sealable layers, these laminates ensure secure sealing for pouches, sachets, and rolls, making them ideal for vacuum and various flexible packaging formats.

Attractive Customizable Finishes

Choose from glossy, matte, or metalized surface finishes combined with rotogravure or flexographic printing up to 8 colors. We offer customized designs and branding, enhancing product visibility while ensuring food-grade safety and high tear resistance.

FAQs of Food Packaging Laminates:

Q: How do multilayer laminates benefit the packaging of food products and pharmaceuticals?

A: Multilayer laminates combine materials like PET, PE, BOPP, and aluminum foil to deliver robust moisture, gas, and aroma barriers. This structure ensures products remain fresh, protected from contamination, and extend their shelf life, making them ideal for food items, spices, dairy, and pharmaceuticals.Q: What processes are used to manufacture these food packaging laminates?

A: Our laminates are produced using advanced multiple extrusion and lamination processes. These methods bond different materials together, creating strong, flexible films with excellent barrier and mechanical properties suited for pouch, roll, and sachet formats.Q: Where can your packaging laminates be applied?

A: They are widely used in packaging snacks, spices, confectionery, dairy, and pharmaceutical products. The laminates accommodate various packaging typesincluding vacuum, pouch, roll, and sachetoffering versatility for diverse industry requirements.Q: What shelf life and product protection do your laminates provide?

A: Our laminates offer a shelf life of up to one year, depending on storage conditions and the packaged product. Their high-performance barrier features protect contents from moisture, oxygen, and external contaminants to maintain product integrity and freshness.Q: Can the laminates be customized for branding and packaging requirements?

A: Yes, we provide extensive customization options, including film length (up to 2000 meters), width (up to 1300 mm), thickness (20-250 microns), printing in up to 8 colors, and tailored finishes (glossy, matte, metalized, and transparency levels). Design and color can be adapted to match your brand specifications.Q: How does the heat sealable feature improve packaging efficiency?

A: Heat sealable laminates enable secure and reliable sealing on packaging machines, ensuring the contents are protected against leakage and tampering. This feature enhances packaging speed and efficiency, supporting high-volume production lines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free